JAX Chemical offers a wide range of chemical products for cleaning and applying a variety of finishes to your metals. With over 40 years of experience in the business of metal finishes, JAX is a trusted brand in many industries. Their patinas are commonly used by jewelers but are also often seen in lighting, furniture, decorative hardware, sculpture, stained glass, and even architecture. These products are often used to replicate natural wear, tarnish, and distressed finishes on metal in restorations and reproductions of antique items as well as to create new and unique effects on metals. We get a lot of emails with questions about various JAX applications, and were hoping to clear up some of our most frequently asked questions here, as well as provide an overview of some of the JAX product line.

An Overview of Working with Patinas

An important thing to know about patinas is that the chemicals are formulated to cause a chemical reaction with the metal that they are applied to – this means a few different things.

Type of Metal is Critical

First, you need to know the type of metal that you are working with in order to patina it. For example, brass and aluminum can react completely differently to the same chemical. Often, when attempting a restoration on old hardware or a piece of costume jewelry, it can be hard to know exactly what it’s made of! However, it’s critical to determine this before you start brushing chemicals on. You may not get the desired result, or worse, you may damage your metal.

Metal Must be Clean

Since the chemical must be in direct contact with the metal to cause a chemical reaction, it goes without saying that any lacquer or coating must be removed before you can use a patina. It’s also just a good idea to wash your metals right before applying patinas. Some metals come with a thin layer of invisible residue from manufacturing that can inhibit patinas, and even pieces that were washed fairly recently can have skin oils from being handled which can cause the metal to resist the patina.

Safety First

Many patinas are hazardous chemicals, to some extent. They often call for safety precautions when handling, such as wearing gloves, a respirator, and/or safety goggles, as well as some environmental precautions when disposing of spent chemicals. See JAX MSDS sheets with more detailed information here.

Placement is Important

Since a patina is just a chemical reaction on the surface of a metal, it is not permanent. When using patinas, try to think about the future wear that the item may encounter. For example, a ring bears a lot more friction in its life than earrings do. So, while applying a blackening patina to an entire ring may be tempting – keep in mind that the patina may rub off. The pattern of wear is also worth considering. While the patina will wear off the high areas, it will usually remain in cracks and crevices. In some cases, this is a very desirable effect that mimics an aged look on your metal. Many people will wear the highlights off the patina deliberately with steel wool or sandpaper.

JAX Products

Oxidizers

In jewelry, we often use patina to either replicate a natural aged finish, or to retore a finish that has been lost due to time, wear, or cleaning. Some of the most common products that are used to restore these finishes are types of oxidizers – chemicals that tarnish or blacken metal. These effects range from a natural brown-colored tarnish, to a dark black color, to a cool grey finish. Depending on your end goal, one of these finishes could work well to replicate a natural tarnish or the look of a different material or metal. JAX Flemish Grey-Black can produce a finish on brass and copper that resembles pewter, and JAX Brown does an excellent job of replicating the natural look of tarnish on these metals.

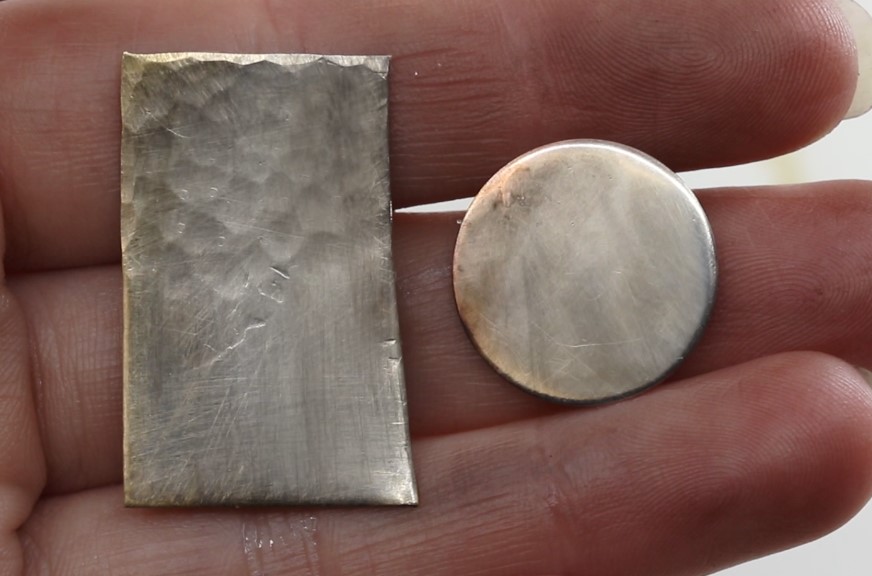

Several JAX patinas are formulated to make a black finish on different metals. They have these blackening solutions for silver, gold, copper, bronze, brass, aluminum, iron, steel, nickel, and pewter. These vary in their exact composition and effect, as you may have seen in our video. The below photo demonstrates the difference in results on a few different metals.

Rust and Verdigris

Some other, more complicated finishes that are often achieved with patinas are states of decomposition of metals. Effects like rust on iron and steel, or verdigris on copper and brass would be examples of this. One finish that JAX is particularly famous for is the JAX Green patina. This chemical is used to produce an authentic and consistent verdigris on copper and brass. The green patina is commonly used in sculptural and architectural situations, but also makes a beautiful finish on jewelry. JAX also makes a patina called Antique Rust which is great for creating rust on iron and steel. It is often used in hardware and sculpture.

Plating

JAX carries a couple of different plating solutions – copper and silver. These both plate a thin layer of metal onto your piece without requiring the heat or electricity that are necessary for most plating solutions. This makes these solutions very accessible to people who are just looking for some coloration, and not for a thick durable plating provided by an expensive electroplating setup. This also makes them well-suited to larger items, as these plating solutions can be painted on, and do not have to be dipped.

Colorants

Another interesting patina that JAX has is the JAX Gold Finish. Gold Finish is a colorant that produces a simulated gold color on aluminum, brass, and silver. One common question we get about the JAX Gold Finish is whether or not it is suitable for replacing plating on worn hardware, such as the hardware on a purse or pieces of hardware in your home such as doorknobs. Unfortunately, this is generally not a suitable application for this product. Usually, the hardware in your home or on your bag is not going to be made of aluminum, brass, or silver. Additionally, this product will likely rub off quicker than the plating would, as it does not deposit a layer of metal onto your hardware. It is best to take the items to a professional for replating or to have the hardware replaced. This patina is great for making a beautiful gold effect on aluminum, though! It has a lot of potential for artistic applications, and it’s fun to watch the colors of the chemical reaction. Check out our video earlier on this page to see JAX Gold Finish in action.

Application Techniques

When working with patinas, the results you achieve with vary based on application technique as well as other factors. While these are going to differ between chemicals and between situations, here is some general information about applying patinas.

Most patinas can be applied through dipping or brushing, and many patinas can also be applied by fuming. We’re going to stick to dipping and brushing in this article, as these are the recommended approach for most JAX products. Lots of people have their own methods for applying patinas, and a lot of working with patinas can be trial and error. Getting the right finish, especially when trying to replicate a specific natural finish, can take a lot of experimentation with techniques.

Dipping or Soaking

Since patinas are generally not instantaneous, with developing/drying times ranging from a few seconds to multiple hours, if you’re looking for a uniform finish that is the same color all over the metal, dipping is often the way to go. However, if you’re working with certain fragile or porous gemstones or other materials, there is a chance that submerging them in a chemical will cause damage. Another potential drawback is flaking – when you leave your metal oxidizing for too long in a solution, sometimes the patina will not adhere properly, and will chip off when you rinse the solution off. For this reason, sometimes it’s better to dip, rinse, and repeat – layering the patina until you reach the desired level of oxidization. Some patinas have to dry in order to produce the chemical reaction, and aren’t suitable for soaking in solution. JAX Green and Antique Rust both require drying in order to take effect.

Brushing

The alternative to dipping is brushing. This technique is great if you only want the patina in certain areas, or if you are trying to avoid getting chemicals on delicate components. Brushing also spends less patina. Since it is not recommended that you reuse these chemicals (they will be less effective and have a shorter shelf life once used), if you dip your pieces in the patina you will use a lot more liquid than if you were to brush the liquid on. However, brushing can produce an inconsistent finish. Since the reaction will be developing at different speeds in different places, it may end up having darker and lighter areas or visible brush strokes. This can be great if you want a natural tarnish, as tarnish is not often perfectly uniform.

Finishing

Once you’ve achieved the patina you have been looking for, you may wonder how you will manage to preserve the finish. One way to protect a patina is to apply a clear coat of some sort, such as lacquer or wax. This is a common practice which can preserve a finish and protect it against wear, but many experts and professionals also advise against it for a few reasons. Lacquer can chip, and once the lacquer is chipped, you have to strip all of the lacquer in order to reapply it, this can be time consuming, and can also ruin the finish, calling for reapplication of the patina you worked so hard on. Wax may be less fuss, but it calls for more frequent reapplication. This may work out in some applications, but in jewelry it isn’t ideal. Finally, it can affect the texture and overall look of the patina. A lacquer or wax will usually leave a different texture than the texture of the natural metal. If you are working with JAX Antique Rust or Green, you may find that you like the natural look of the matte finish that the patina provides, and a lacquer could spoil that. In most cases, JAX Chemical recommends not sealing patinas, and letting them wear naturally.

Experimentation

In closing, it’s important to remember that using patinas can often be an experimental process. The surprise of what it looks like in the end can be half the fun! When trying out a new patina process, it’s usually a good idea to test run it on some scrap metal or get some practice using the chemicals on a piece that you are less invested in before you use them on your masterpieces. 🙂